STRAIGHT-LINE ACURACY

PRECISION YOU CAN SEE

QUALITY GARUNTEED.

The milling department at Straight Line Hardwoods is the heart of our custom craftsmanship. Equipped with state-of-the-art machinery, including CNC lathes, gang rips, helical-head planers, and precision moulders, our team of skilled craftsmen transforms raw hardwood into perfectly milled components with unmatched accuracy. Every board, every molding, and every custom profile is carefully processed to meet the exact specifications of your project.

From intricate custom moldings and cabinet trim to specialty profiles and architectural millwork, we ensure that each piece is cut, shaped, and finished to deliver clean lines, consistent dimensions, and a flawless surface. Our modern technology allows for quick setup without sacrificing precision, meaning small runs or large production orders can be completed efficiently while maintaining the high standards our customers expect.

Beyond the machinery, it’s our expertise that sets us apart. Our craftsmen bring decades of experience and an eye for detail, ensuring that each cut, curve, and profile is executed perfectly. The result is custom-milled hardwood components that are ready to install, visually stunning, and built to last for generations.

Our milling department doesn’t just produce parts—they lay the groundwork for every masterpiece, giving every project the quality, precision, and durability that define our reputation.

CNC Lathe

This advanced CNC lathe produces precision-turned custom posts for the kitchen cabinet industry. With the ability to turn posts up to 14 inches in diameter and 10 feet in length, it offers exceptional versatility. In addition to our standard line of posts, this computerized machine allows us to design and turn custom profiles to meet virtually any customer specification.

Profile Grinder

Using our specially designed Weinig Profile Grinder, we have the capability to create custom moulding profiles with precision and consistency. Whether you’re building a new home and need custom mouldings to match your vision, or restoring a 120-year-old home that requires exact profile replication, this equipment allows us to grind the knives needed to produce accurate, seamless results.

Moulders

Our Weinig Moulders are state-of-the-art, late-model machines designed for precision and efficiency. We operate one 5-head moulder and two 6-head moulders, with the 6-head machines featuring computerized setup technology for fast, accurate changeovers. This advanced system ensures consistent, exact profile matches with every setup.

We recognize the importance of quick turnaround times, especially for small production runs. With this equipment, we’re able to deliver the speed, accuracy, and craftsmanship required to meet the demands of today’s evolving cabinet industry.

CNC Template Machine

When creating custom profile knives, the process begins with manufacturing a Nylon Template. Using computerized technology, we take a simple drawing, digitize it, and precisely cut the profile template. This template is then placed into the profile grinder, where it serves as the guide for accurately cutting the custom profile knives.

Gang Rip Machine

SLH operates two Weinig KM-310 Gang Rip machines designed for speed and precision. These machines feature a fluid-filled arbour system that allows blade adjustments for the next setup without removing the arbour. This advanced technology enables setup times of approximately three minutes.

Because of this quick setup, material can be processed efficiently and prepared for the next stage of moulding with minimal downtime.

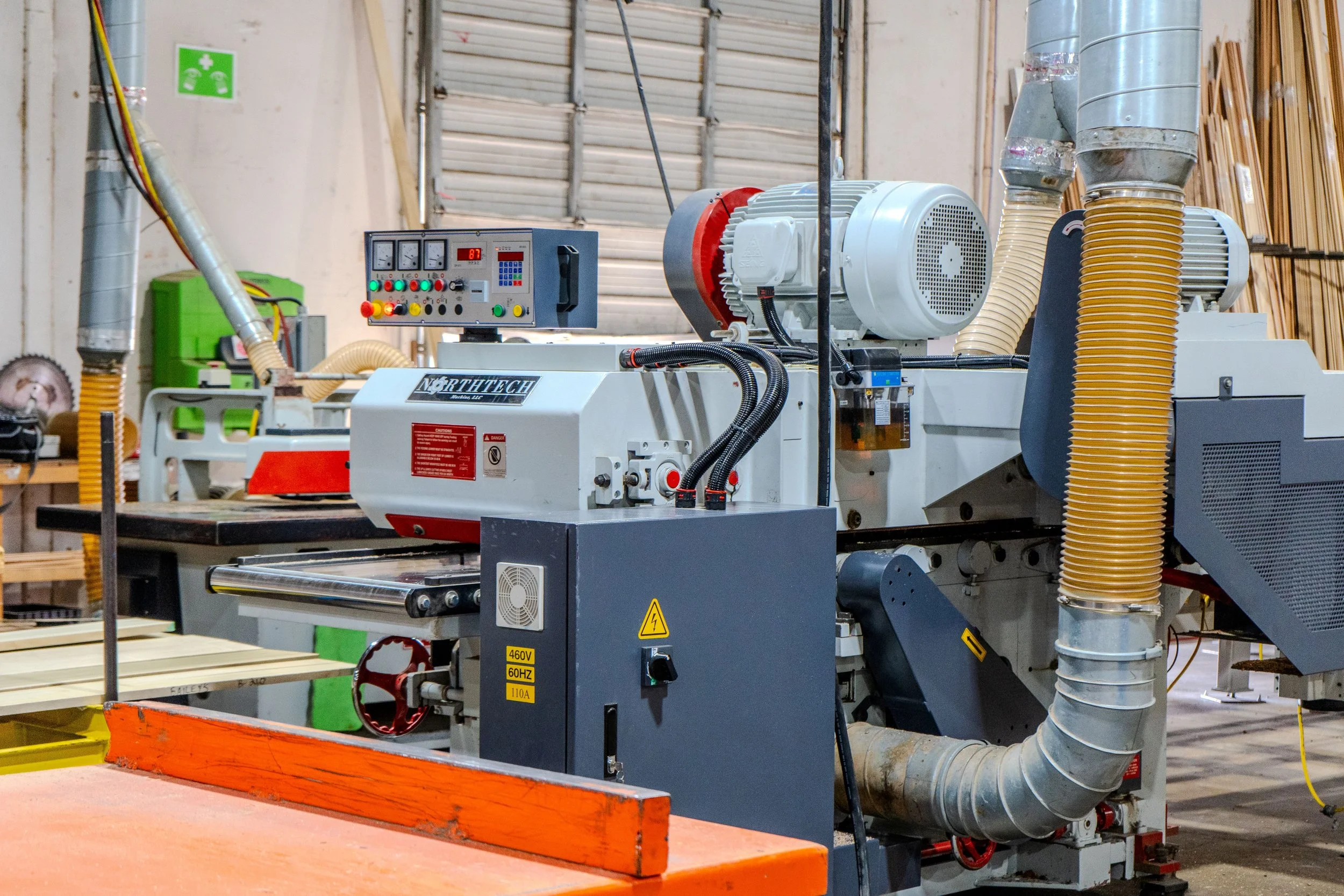

24” Double Sided Planer

SLH operates two 24-inch Double-Sided North Tech Planers, both equipped with Helical Heads and Carbide Insert Tooling. The helical head design planes lumber with a smooth slicing motion rather than the traditional straight-knife chopping action, producing a cleaner surface finish and reducing the amount of sanding required.

Both the top and bottom cutterheads are designed to slide out quickly, allowing for fast replacement of chipped or worn carbide inserts. This efficient design minimizes downtime and keeps production moving without sacrificing finish quality.

Straight Line Rip Machines

SLH operates two straight-line rip machines, each capable of producing thousands of board feet per day. These machines are designed to establish a perfectly straight reference edge on every board, ensuring consistent width, accuracy, and stability throughout the milling process. Board after board, they deliver clean, straight cuts that are essential for producing high-quality mouldings and millwork.

Built for heavy-duty production, these machines handle demanding workloads while maintaining tight tolerances. Their precision and durability allow us to prepare material efficiently and accurately, giving our customers lumber that is ready for the next stage of processing and built to perform exactly as expected.

Hours of Operation

MONDAY - FRIDAY

8:00 AM- 5:00 PM

Receiving Hours

Available for Will Call Customers & Deliveries

MONDAY - FRIDAY

8:00 AM- 3:00 PM